Opening up the boat.

When I get on board, I run through a series of steps to open up the boat and its systems. Starting in the starboard stern, I work through the boat forwards up the starboard hull and then to the port stern.

Starboard Hull.

1) Open seacock for water to the two seawater deck pumps and saltwater tap in the galley.

2) Check the oil and coolant on the starboard engine.

3) Open the seacock for the air-conditioner cooling.

4) Open the seacock for the genset.

5) Install the log paddle-wheel.

6) Open the seacock for the starboard toilet flush.

1) Open seacock at back of starboard engine bay. Lift the lid above it.

Saltwater seacock off

Saltwater seacock on

Aircon seacock on

Under the floor of the galley is the seacock for the genset. Turn it on only when you want to use the genset, and turn it off when you have finished. The reason for this is that the genset is about one metre above the waterline, and the water pump in the genset has to suck water up before it starts cooling. There is a non-return valve in the hose, but if the boat stands for any length of time, water can sneak past it, and when there is no water on the impeller, the water pump can struggle to prime itself, and the impeller can get burnt out. This is less likely to happen if the sea-cock is left closed.

Under the floor of the starboard main guest cabin, under the carpet, are two square hatches. The aft one contains the log. I remove the paddle-wheel when leaving the boat. It needs to be replaced before the log will measure speed through the water.

There is a trick to this manoeuvre. When you unscrew the blank and take it out, seawater pours into the boat. So you must be ready to immediately put the paddlewheel into the hole, push it down, align the arrow on its top so it is pointing forward towards the bow, and then screw the collar up tight.

Because the water comes into the bilge, I remove any plastic containers before I do this, and put an old towel into the floor of the bilge around the area of the log to catch as much of the seawater as possible.

When moth-balling the boat, the paddle-wheel get removed in the reverse of the operation described above. I will check the paddle-wheel is running freely and sometimes clean it and give it a squirt of Inox.

Under the carpet at the front of the starboard cabin, just aft of the toilet door, is another square hatch. It contains the seacock for the toilet flush. It needs to be turned on.

Toilet seacock off

Toilet seacock on

Inside the locker forward of the starboard toilet is a holding tank. If you want to empty the tank at sea, the holding tank cock is below it. It should be closed if the toilet is being used while the boat is in a marina, etc.

Port Hull

1) Check oil and coolant in port engine.

2) Turn on toilet seacock.

3) Turn on watermaker seacock.

The port engine lives behind the door in the back of the port shower.

The white fibre-glass floor forward of the shower, under the port toilet needs to be lifted carefully. A bit tricky. Best done from the shower area.

Both the watermaker seacock and the toilet flush seacock need to be turned on (handles point up).

Electrical power

If on the marina for any time, the boat needs to be connected to the 240v AC supply on the dock. There is a longish yellow cable that plugs the male end into the dock and a screw-in female end just below the port steering wheel.

Inside the top cupboard on the port side near the chart table and main cabin door, are various electrical controls.

This 240v power switch should normally be 'Off'. After connecting the yellow wire between the 240v source on the dock and the boat, this switch should then be turned onto 'Shore'.

It is better to start the genset with the switch 'Off', and only turn it to 'Ship' once the genset has been running for a minute or so.

These are the four 240v AC circuit breakers. If too much power goes through one, it may trip off (down). This is most likely to happen when connecting up either shore power, or the genset, when too many things are on and trying to draw all at the same time. Eg, the water-heater is active, and the batteries are also low and wanting to draw a large charge. Or the charger is working hard and the microwave is also turned on. It may be better to turn some things off and then try again by turning the circuit breaker back on (up).

There is another circuit-breaker inside the genset case, in the locker in front of the mast. This can also trip off when too much current flows. It is a small black switch on the port side of the genset near its bottom. It is to be suspected when the genset has been charging well, and suddenly stops charging. The genset case needs to be opened by undoing a series of rubber toggles.

This battery monitor shows the state of charge of the batteries. If I want to provoke the charger into action (for example if we want to go to sea with full batteries soon), I will trigger the Magnasine charger by pressing and holding down the 'Charger' button below.

This picture shows that it is charging at 122 amps after doing that.

When away from shore power, if 240v AC is needed (e.g. for the microwave), the inverter is turned on by pressing the 'Inverter' button above. One press is needed to get the inverter out of sleep mode; the second press turns the inverter on.

The Genset.

To charge the batteries fast when away from shore power, the genset can be used. It consumes diesel fuel from the starboard fuel tank under the galley floor.

Before starting it, one should ensure that the 240v power switch is off.

Next press the On/Off button on the left. See below.

Next hold down the 'Start' button and listen for the sound that the genset has started properly. It is easiest to hear if you put your head inside the main port cabin. It takes a few seconds.

After starting it, if the genset has not been used for a while, go to the stern of the boat and look forwards under the bridge deck. Below the mast area there should be water splashing down. If there is not, the water cooling system may have failed to self-prime. The genset sounds loud. It may stop itself automatically.

If all is well, the 240v power switch can be turned to 'Ship'

After a few seconds, the charger should detect the supply of 240v AC from the genset, and start charging, as above.

Priming the genset seawater cooling system

If the boat stands for a while, the seawater may creep past the non-return valve in the genset cooling line, and the genset may fail to prime itself when it is started. It is possible for a dry impeller to burn itself out, in which case it would need replacing.

One approach to remedying the problem that can be tried first is to prime the genset cooling line with saltwater from the galley tap into the line downstream from the brass non-return valve.

Take a short hose. Jam one end over the saltwater tap by the sink, and stick the other end up inside the fatter hose you have removed. Squeeze a rag or towel around the join. Turn on the saltwater tap. Start the genset. Once it is all running, with water splashing down under the boat, the hose in the cooling line can be reconnected as above and the hose-clamp retightened. Remember the genset seacock must also be on.

The level of water on the boat can be seen on the fuel/water gauge. Buttons select the tank:

1) Port fuel. Max = 160 litres

2) Water. Max = 740 litres

3) Starboard fuel = 160 litres.

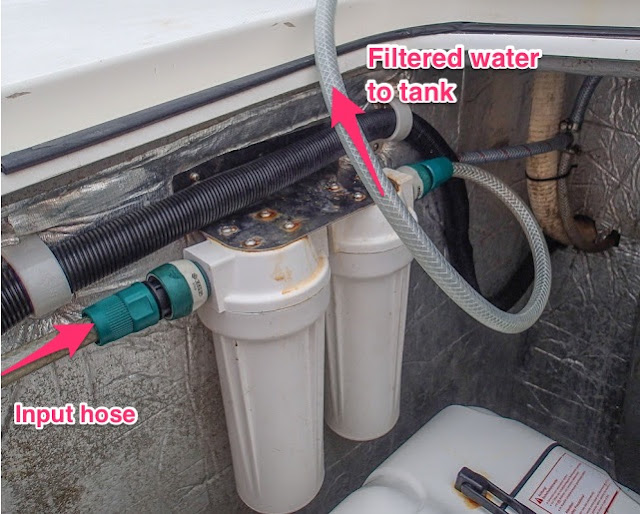

These filters live inside the locker in front of the mast.

It is best to run the freshwater hose for a minute (e.g. by spraying the boat) before putting water into the tank, in order to flush out the plastic taste. Check the taste of the water before filling the tanks.

The short hose from the aft side of the filters comes out of the locker, into the water intake, like this.

Then the hose from the tap is attached to the front end of the filters. Progress can be followed on the meter. If the tank is full, water spills over the foredeck into the water.

Gas

This solenoid switch lives on the wall of the galley just astern of the fridge. The LED light doesn't work, and it should be switched off when the gas is not needed.

When a gas bottle runs out, the hose from the connected one needs to be undone (gas screws are always anti-clockwise to do up, clockwise to undo), and the spare bottle swapped with it. The empty bottle should be filled at the earliest opportunity, so there is always a full spare available.

Diesel Fuel

There are two 160 litre stainless steel diesel tanks in the bilges, one in each hull. The starboard one supplies the starboard Yanmar 3YM30 engine, and also the Fischer Panda genset. The port one supplies the port Yanmar engine. The port engine heats hot water.

The decision which engine to use when only one is needed might be affected by these facts. If you are at risk of running out of hot water, favour the port engine. If you are at risk of needing extra charging capacity, make sure you have fuel left in the starboard tank.

In addition to the steel tanks, there is an extra 100 litre fuel bladder in the port bilge.

It is connected to the port stainless fuel tank by hoses and an electric pump. Because the pump leaks diesel fuel, there are two isolating taps in the hose line which need to be opened before fuel can be pumped from the bladder into the stainless tank.

The pump is controlled by a small switch in the electrical cupboard as shown here.

When the contents of the bladder have been added to the stainless tank, the fuel gauge should show about 100 litres more than before. Press button 1.

Turn off the hose taps after transferring the fuel.

When filling the bladder with fuel, there is a Mr Funnel filter in the port engine room on top of the holding tank.

It can be inserted into the fat bladder intake hose and diesel fuel can be filtered as it goes into the bladder. The big lever tap must be turned on.

There are also two 20 litre yellow plastic jerry-cans in the genset locker in front of the mast.

After filling fuel tanks, it is my practice to add Fuelmaster at a ratio of 2.5 ml per 10 litres into each tank. There is a bottle in the port engine bay, with a small measuring syringe in the funnel under the hot water tank.

Starting the engines

The engine battery must be turned on. The lower of the two red round knobs should be rotated horizontal, as shown.

There will then begin a squeaking noise from the electronic throttles. They are asking which of the two sides you wish to use. There is a small button on the front side of each pair of throttles. Press the one you want to use. (Usually the port side). The squeaking stops, and some red lights appear on the active throttles.

If you ever want to change to using the opposite side, ensure that the throttles you want to use are in neutral and press the little button on that side. The light will turn on, and the new side will become active.

Turn the keys to start. Check that water is coming out of the exhausts on each side.

Normal cruising speed is 2400 revs.

The boat has folding Gori propellors. They have a higher pitch in reverse, than in forward. A trick for getting an extra knot of speed when motoring or motor-sailing, is to start the boat in reverse, get up some movement, and then throw throttles to forward. This has the effect of setting up the higher pitch position of the prop blades, which cannot close while the boat is moving in reverse, so when you go forward, the higher pitch is retained. It works best in smooth water.

The 'Overdrive' mode can cause the props to cavitate in rough seas, or when there is a strong headwind.

The 'Overdrive' mode is a bit like using a higher gear. There are times when you need the lower gear.

More information about safety equipment can be found here.

Fridges

There are two fridges. The cockpit fridge is controlled by a little box on the left inside the port engine room behind the shower.

The fridge in the galley is controlled by a switch above the chart table.